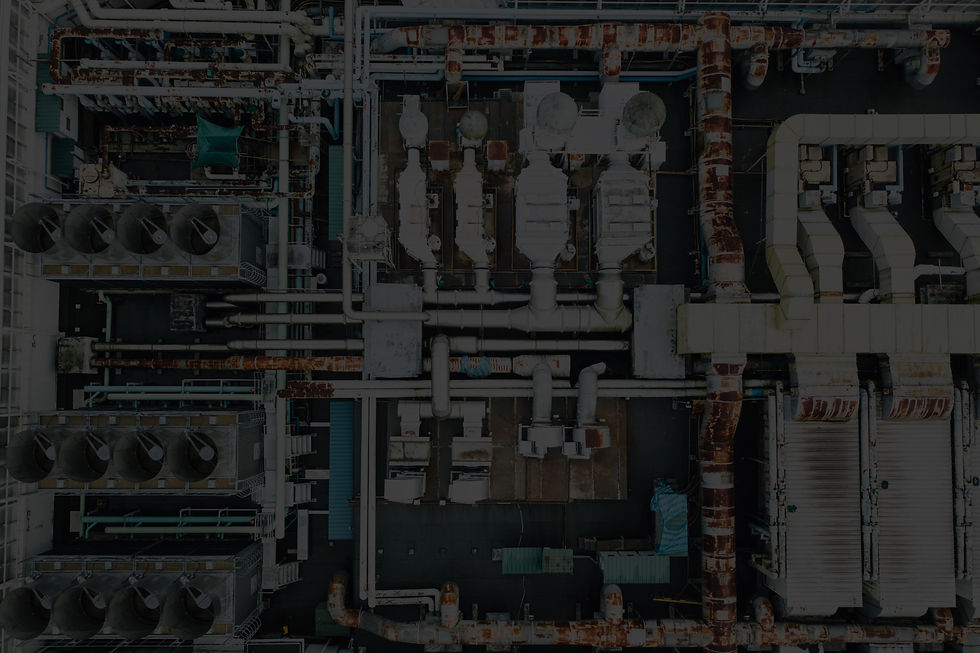

Lime production line

Our design uses vertical preheater, rotary kiln, vertical cooler machine composed of active lime calcination system, including raw material conveying system, firing system, finished product conveying system, kiln flue gas treatment system, coal grinding system technology, civil engineering, general layout, electrical and automation of preliminary design.

Brief Introduction:

Our design incorporates a vertical preheater, rotary kiln, and vertical cooler to compose the active lime calcination system. This includes systems for conveying raw materials, firing, conveying finished products, treating kiln flue gas, and grinding coal. Additionally, the preliminary design covers technology, civil engineering, general layout, and electrical and automation aspects.

Technical features:

When selecting a production process scheme, conduct thorough investigations and comparisons of proposals based on diligent research. Wherever possible, adopt mature and reliable new processes and technologies to ensure that the technology is advanced, economically reasonable, and genuinely reliable. The design of electrical and automation control should consider advanced technology, with equipment and instruments that are mature, reliable, and straightforwardly applicable.

Diligently implement national environmental protection policies, pay attention to environmental protection, and actively carry out the principles of energy saving and consumption reduction.

Quicklime can be used to manufacture calcium carbide, liquid alkali, bleaching liquid, bleaching powder, and is also used in tanning leather, metallurgy, purifying wastewater, and can be used in steel, pesticides, medicine, non-ferrous metals, fertilizers, leather making, manufacturing calcium hydroxide, for drying laboratory ammonia, and for dehydrating alcohols, among other applications.