Gypsum Powder Production Line

With the technology of calcination first and grinding second, raw material is conveyed into calcination equipment by feeder evenly, such as Rotary Kiln and Chukanabe, to dehydration. Based on different fuel, it can be external

Brief Introduction:

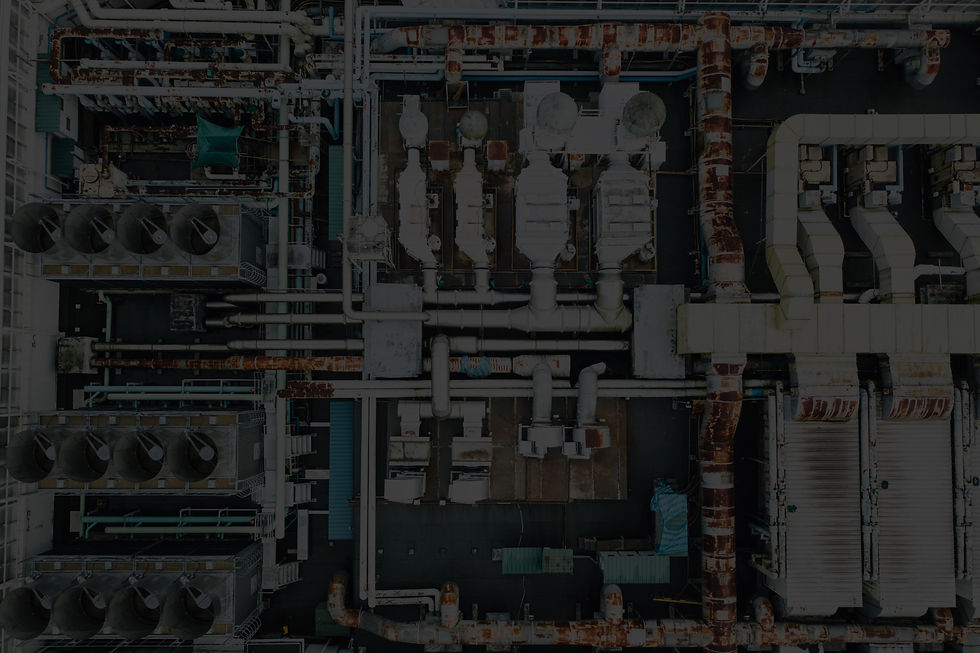

Our production line utilizes the technology of calcination first and grinding second. The raw material is evenly conveyed into calcination equipment, such as a Rotary Kiln or Chukanabe, for dehydration. Depending on the fuel used, it can be either external or internal combustion. After aging, the material is ground in a Pendulum Pulverizer. Qualified final products are then packed in a packing silo. This production line boasts high automation, with emissions meeting environmental protection standards and product indices reaching national standards.

Technical features:

The building gypsum powder production line, with an annual capacity ranging from 10,000 to 100,000 tons, includes project design, equipment supply, installation, commissioning, and standard achievement.

Product Application:

★Gypsum powder production line with 30,000 ton annual capacity in Dammam, Jordan

★Gypsum powder production line with 60,000 ton annual capacity in Saudi Arabia

★The first-stage project of gypsum powder production line with 60,000 ton annual capacity in Johor Bahru, Malaysia.

★The second-stage project of gypsum powder production line with 80,000 ton annual capacity in Johor Bahru, Malaysia.

★Gypsum powder production line with 60,000 ton annual capacity in Egypt.

★Gypsum powder production line with 30,000 ton annual capacity in Ethiopia.

★Gypsum powder production line with 60,000 ton annual capacity in Jakarta, Indonesia.

★Gypsum powder production line with 60,000 ton annual capacity in Thailand.